Excitement About 24hr Media

Table of Contents8 Simple Techniques For 24hr MediaSome Of 24hr MediaThe smart Trick of 24hr Media That Nobody is DiscussingThe Best Guide To 24hr MediaThe Greatest Guide To 24hr Media

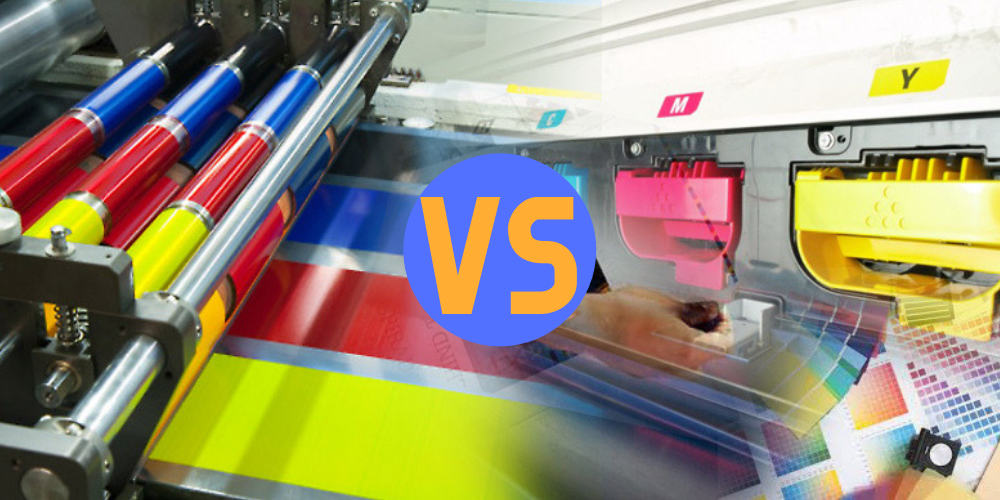

Advancements in print innovation are altering the communications playing field when it concerns quality, cost and advanced capacities. Countered printing and electronic printing are the significant processes by which print work are carried out both making use of four-color printing techniques. Each choice has its benefits, offering different strategies to fulfill the needs of diverse manufacturing jobs.

Commonly, this has been the most constant method for exactly keeping color suits, making it perfect for print runs that just require static printing such as pre-printed kinds, brochures, flyers, calling card, and mass postcard mailings. Nonetheless, due to the static nature of litho printing, it is not optimal for variable print items that will certainly be mailed to specific recipients such as statements, letters, and individualized postcards.

8 Simple Techniques For 24hr Media

The most recent innovations in print technology are aiding to bring many of balanced out's advantages into the electronic printing globe genuinely transforming the face of modern-day printing! There are some key differences between Offset Printing and Digital Printing.

Today's digital print devices is among one of the most sophisticated on the market. Below are several of the largest advantages of utilizing electronic printing: control the electronic print area, with full-color printing finished in one procedure and effortlessly published straight from a print data. Without an extensive set up process, the calibration time of a particular task is reduced, contributing to quicker print time and overall distribution.

The inkjet printing process has actually helped to reinvent the sector as well as the top quality and rate of the output. The current inkjet innovation can print on standard offset supplies with dull, silk, and shiny finishes. Premium digital print paired with software-managed shade monitoring techniques includes optimum value to print items and makes manufacturing processes extra reliable than offset.

Some Of 24hr Media

(https://hearthis.at/fred-mack-mn/set/JGlI4/)

Precise quantities of ink and printer toner are utilized to stay clear of waste. Environmentally friendly and biodegradable inks and printer toners are additionally offered for even more sustainable printing. Digital print also eliminates the demand to clean plates or blankets with official website hazardous chemicals at the end of the printing process. As the top quality of electronic print solutions boosts, the benefits end up being progressively obvious and helpful.

Variable information helps services reach their precise consumers and audience with uniquely-created and customized web content. As modern technology improves, the top quality of electronic printing has become second-to-none, with greater detail, color match capacities and total precision. Without the need to clean plates or make use of excess ink, electronic printing is likewise much less wasteful and generally more eco-friendly.

Traditional printing methods, such as countered lithography ("balanced out") and flexography ("flexo"), involve numerous make-ready steps to move an initial picture to a substrate. These techniques need the manufacturing of a series of plates placed on a cyndrical tube to move ink that develops the desired image when incorporated on paperboard and various other product packaging products. Signage.

All about 24hr Media

Digital printing, with less moving items, is more nimble than countered in this regard.

It's a method to mix your packaging and advertising techniques. Minimized set-up time saves cash on the front end. And because these are not large bulk orders, smaller companies can pay for to publish without having to fulfill the greater and more costly print limits of conventional printing. Digital printing assists secure your brand name versus counterfeiting by including overt and hidden options on your packaging.

Make certain you collaborate with a printing and product packaging partner that has the ideal certifications. While eleventh-hour printing and customization are a huge benefit, digital might not constantly be the ideal technique for you. For instance, balance out printing has the benefit of cost-effectiveness with big print runs, especially those with innovative ornamental results and specialty layers.

Not known Incorrect Statements About 24hr Media

The favorable plate, with its smooth surface, attracts oil-based inks and pushes back water. In comparison, the negative plate, with its harsh texture, takes in water and fends off oil. Rubber rollers are after that made use of to transfer the image from the plate to the corrugated surface area.

Corrugated paper can in some cases prove to be a difficult surface area to print on, but Litho prints to a different surface area and is then laminated to it, making it simple to publish top notch pictures. It can be extremely regular, also for long terms. The much more you print, the cheaper the costs come to be for Litho.

What Litho doesn't give you is specifically what Digital does, personalization. Pricey established up Longer turn-around No Variable Data Printing Smaller sized shade gamut, shades can be less intense Digital printing is the process of printing electronic pictures directly onto the corrugated substrate making use of a single-pass, direct-to-corrugate strategy.